If you’ve been following the debate around how to decarbonise our heaviest vehicles, you’ll be aware that it’s essentially been a three-horse race. Out in front are battery trucks, with megawatt chargers soon to give them a boost. Close behind are hydrogen fuel cell trucks, accompanied by all the heated arguments that hydrogen always seems to generate. And the outside bet is still ‘electric road systems’, i.e. pantograph trucks with overhead wires on key stretches of motorway.

Well, it seems we have a late entrant which might just have the potential to pull off a surprise win – battery swapping. A company called Ample this week announced a partnership with Mitsubishi Fuso Truck and Bus Corporation to trial its battery swap technology with the Fuso eCanter truck in Japan.

For those not familiar, battery swapping has a bit of a chequered history. The idea is really old, first proposed in 1896 it was used successfully for electric trucks in the US from 1910 to 1924 and has been used for forklifts worldwide since the 1940s. However, for modern EVs the concept fell out of favour almost exactly a decade ago with the huge failure of battery swap company Better Place. CEO Shai Agassi convinced investors to part with $700 million as of 2011, but in 2013 the company filed for bankruptcy amid allegations of wasteful spending and financial mismanagement.

Since the failure of Better Place, battery swapping has had a very low profile, but with some uses particularly in China. However, with Ample raising over $160 million in funding and multiple plaudits in the press, it seems that maybe investors are ready to take another serious look at the idea.

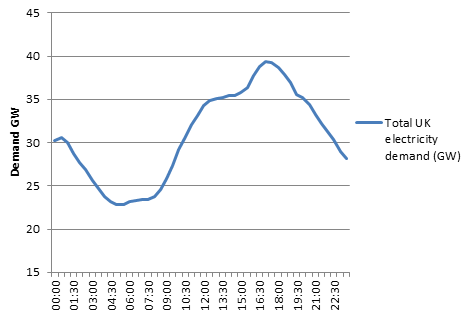

So what are the pros and cons? The reason it was first in operation over a century ago is obvious – swap the battery and you can effectively recharge your vehicle in minutes. The other big plus, which is more pertinent today, is that the actual recharging can be managed over many hours, reducing peak energy demand at recharging locations. That’s much easier to manage than hooking up megawatt fast chargers, and could be integrated more easily with nearby wind or solar.

And the downsides? Well, there are two main drawbacks. The easier one to manage is technical – the swap stations need to be automated, which requires complex robotics, and there’s some risk of damage to the expensive battery packs. It won’t be easy, but it’s certainly not impossible, more a question of how cheaply it can be done to the required standard.

The tougher problem is persuading multiple vehicle manufacturers to standardise their battery packs, and their location in the vehicle. Personally, I think the odds of success are higher for trucks than cars. There are fewer truck manufacturers and fewer models, the vehicle architecture is more standardised and batteries are often located in an easy to access part of the chassis between the wheels. And the range problem is bigger for trucks, so there is just a greater incentive to find a novel solution – manufacturers have already formed alliances to develop megawatt charging and hydrogen refuelling.

As things stand, Ample seem to be focused on the car market, which is understandable from the point of view of attracting investors. Most car brands are part of large multi-brand groups, often sharing common architecture for their EVs, so it’s not impossible they may try battery swapping – especially in America. However, as EV range and charge-point availability are rapidly increasing, the niche for battery swapping (and fuel cells) in cars is rapidly shrinking. I wouldn’t be at all surprised to either, (a) see Ample pivot to focus on heavy commercial vehicles, or, (b) see a new commercial vehicle battery swapping company pop up. They will have to come from behind, but I think the competition to power long range heavy vehicles may soon be a four horse race.